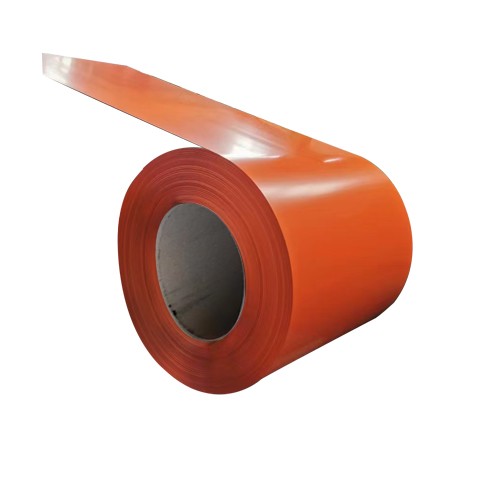

China trusts color coated steel coils in manufacturing. They're steel sheets coated in China, known for quality, affordability, and versatility. Used in construction, cars, and appliances, they resist rust and look good. This guide explores their benefits and uses, showing why they're favored worldwide. Whether you're a manufacturer or consumer, these coils offer reliability and durability.

A coated steel coil is like a steel sheet with added protection. We apply this protection in different ways, like dipping the steel in hot zinc or using electricity to put zinc on it.

The goal is to shield the steel from things like water, chemicals, and rubbing. This keeps rust away and makes the steel last longer. You can use it in many ways, like for roofs, car parts, or buildings.

Coated steel comes in different kinds, like galvanized or painted. Each type is good for different jobs.

China-made color coated steel coils offer several benefits that make them a popular choice in various industries and applications. Here are some of the key advantages:

Cost-Effective: China earns its reputation for cost-effective manufacturing processes. Color coated steel coils produced in China are often more affordable than those from other countries, making them an attractive option for businesses looking to save on production costs.

Wide Range of Options: Chinese manufacturers offer a wide variety of color options and coating materials. This allows customers to choose from an extensive palette of colors and coatings to suit their specific needs and aesthetic preferences.

High-Quality Manufacturing: Many Chinese steel manufacturers adhere to strict quality control standards and employ advanced technology in their production processes. This ensures that the color coated steel coils meet international quality standards and are durable.

Customization: Chinese manufacturers often provide customization options, allowing customers to specify the dimensions, coatings, and colors of their steel coils. This level of customization ensures that the product aligns perfectly with the customer's requirements.

Quick Production Times: China's efficient manufacturing infrastructure often leads to shorter production lead times. This can be especially advantageous for businesses with tight deadlines or those looking to maintain a steady supply of coated steel coils.

Environmentally Friendly: Many Chinese steel manufacturers are investing in eco-friendly production methods. They use water-based coatings and adhere to environmental regulations, making their color coated steel coils more sustainable and eco-conscious.

Versatility: China-made color coated steel coils are versatile and find applications in various industries, including construction, automotive, appliances, and more. Their adaptability makes them a valuable material for diverse projects.

Excellent Corrosion Resistance: The coatings applied to these steel coils offer superior protection against corrosion, ensuring a longer lifespan and reduced maintenance costs, particularly in outdoor or humid environments.

Consistent Quality: Chinese manufacturers often invest in quality control measures and testing to maintain consistent quality across production batches. This consistency ensures that customers receive reliable products.

Global Export Capabilities: China's extensive export infrastructure allows for the easy shipment of color coated steel coils to customers worldwide. This accessibility makes it convenient for international buyers to source these materials.

Technical Support: Many Chinese manufacturers provide technical support and assistance to customers, helping them choose the right product and offering guidance on installation and maintenance.

The process of producing a coated steel coil involves several steps to create a protective layer on the steel surface. Here's a step-by-step process:

Preparation of Steel: The first step is to prepare the steel coil. It involves cleaning and treating the steel to remove any rust, scale, or impurities. This is essential to ensure proper adhesion of the coating.

Chemical Pretreatment: The cleaned steel is then treated with a chemical solution to enhance its surface properties. This treatment can improve adhesion and corrosion resistance.

Application of Primer: We apply a primer coating to the steel surface. Between the steel and the last layer of protection, the primer serves as a binding agent.

Application of Coating: We apply the desired coating material, which can be paint, zinc, or other metals, to the primed steel coil. Various methods, including hot-dip coating or electroplating, can accomplish this.

Curing: The coated steel coil is then cured or baked in an oven or through a curing process. This step ensures that the coating adheres properly to the steel and achieves its desired properties, such as hardness or resistance.

Cooling: After curing, we cool down the coated steel coil to room temperature. This step stabilizes the coating and prevents deformation.

Quality Control: We conduct rigorous quality control checks to ensure that the coating thickness, adhesion, and overall quality meet the desired standards.

Trimming and Cutting: The coated steel coil may undergo trimming and cutting processes to achieve the required dimensions for specific applications.

Packaging and Storage: Finally, the packaging securely protects the coated steel coil during transportation and storage. Proper labeling ensures easy identification of the coil's specifications.

A coated steel coil is a steel sheet with a protective layer, used to prevent corrosion and enhance durability in various applications.

Processes like hot-dip galvanizing involve immersing steel in molten zinc, or electroplating, which utilizes electrochemical deposition, for applying coatings.

Common coatings include zinc (galvanized), paint, and polymer coatings, each offering specific benefits like corrosion resistance and aesthetics.

Industries like construction, automotive, and appliances use coated steel coils for their resistance to corrosion, durability, and versatility.

Consider factors like the application, environmental conditions, and desired properties (e.g., corrosion resistance, color) to select the appropriate coating type and thickness.

Name:

Mobile:+8618352938159

Tel:+8613486684946

Whatsapp:+8618352938159

Email:sale@numberonesuppliers.com

Add:Room 414,11# Yayuan North Road,Shi Qi Street HaiShu,NingBo,China